Zinc Spray Gun

Price Range : ₹ 45K - 6Lakh

Air Transport

Sea Transport

Land Transport

- Anti-microwave radiation

- Disinfection

- Conductivity

- Heat insulation

- Heat resistance

- Oxidation resistance

4.5 Star Rating by our Precious Clients

- More Details

- Call Now

- Get Latest Price

![]()

Leading Supplier & Exporter

![]()

Trustseal Verified

![]()

ISO Certified

![]()

Manufacturer

A broad range of techniques can be used to apply zinc spray gun coatings to steel including galvanizing, zinc thermal spray gun metallization, electroplating, and zinc-rich paints, among others. These coatings can be used alone or in tandem with a paint topcoat to provide a synergistic result.

This gun is frequently used in conjunction with galvanizing. It can be used to cover existing steel structures and treat steel that is too massive to be hot-dipped, for example. It can be used to restore corrosion protection to areas where galvanizing is removed during fabrication, such as along cuts or threaded ends; and to assure coverage of welds and rivets. It can also be used to repair galvanized surfaces that have been damaged mechanically. A duplex method, which involves applying zinc-rich paints over galvanized or thermal spray coatings, can also enhance the life of barrier coatings.

Hot Zinc Spray Gun

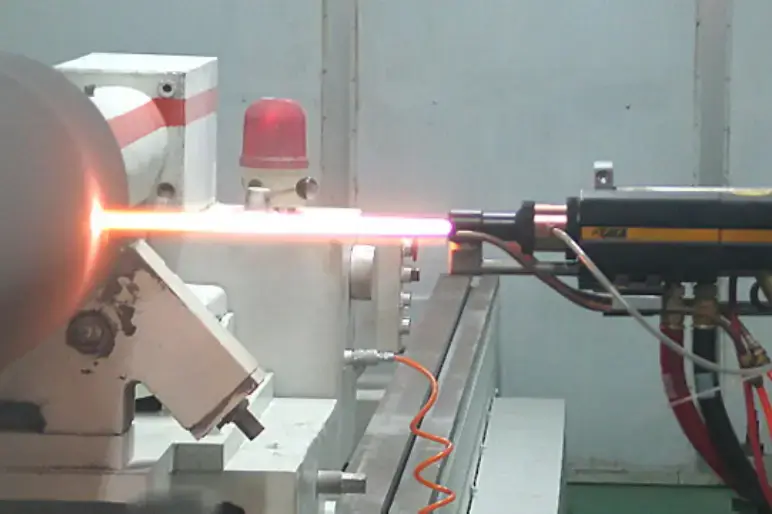

A hot zinc spraying gun, also known as metalizing, is done by putting zinc wire or powder into a heated gun, where it is melted and sprayed onto the part utilizing combustion gases and/or supplemental compressed air to give the required velocity.

This subject has been researched for many years and the literature is well provided with reports on zinc’s performance in various climates, with different alloy additions to the coating and at different coating thicknesses. Each system comes with its own set of advantages so it is important that the correct zinc coating is specified to provide optimal performance under the exposure conditions to which the coating will be subjected.

Specification of Zinc Spray Gun

|

Brand |

Ambica Enterprises |

|

Coating Area (m2) |

4.4 m2 |

|

Cycle Time |

3 - 4 min |

|

Efficiency (%) |

63% |

|

Siphon Plug |

Varies according to wire diameter |

|

Layer Of Thickness |

40 µ |

Working Of Zinc Spray Gun

One object of the invention Zinc Flame Spray Gun, therefore, is to provide a spray gun comprising a liquid container and a cap, therefore, both composed chief of Zinc and having a threaded connection that is reinforced by a collar of zinc, zinc alloy, or similar metal which is materially harder than the zinc. In this zinc is melted down by flame and by pressurized air it is blown to the subject. To sustain the electric arc, the wires are given opposite electric charges and supplied close together, causing the wires to melt. With the help of compressed air and a motor, the molten substance is sprayed onto the prepared surface.

There are several varieties of zinc coatings on the market, each with its own set of features. These features not only affect applicability but also the related distribution and expected service life. The process of processing, adhesion to the base metal, the stability provided at corners, edges, and threads, hardness, coating density, and thickness can vary greatly among the different coatings.

Characteristics of Zinc Spray Gun Coating

Batch Hot-Dip Galvanizing

A sequence of zinc-iron alloy layers with a pure zinc surface layer make up the batch hot-dip galvanized coating. The Zinc Spray coating is metallurgically linked to the steel substrate, making it a part of the steel itself. The binding strength, which is measured in the thousands of psi range, results in a highly strongly adherent covering.

Continuous Sheet Galvanizing

After galvanizing, the continuous zinc spray gun coating is physically wiped across the width of the strip with air knives to provide a homogeneous coating. Cars, appliances, corrugated roofing and siding, and culvert pipe are all made from continuously galvanized sheet steel. The coated product can be appropriately treated for painting, extending its service life. Because of the thin coating, this product is typically used for interior applications or mild corrosive environments.

Zinc Plating Coating

Normal zinc-plated coatings are dull grey with a matte appearance, however depending on the procedure or agents added to the plating bath or through post-treatments, whiter, more glossy coatings can be generated. Screws and other light fasteners, light switch plates, and other small parts are commonly zinc plated. For added corrosion protection, materials used in moderate or severe conditions must be chromate conversion coated. Pure zinc is used for the coating, and it has a hardness of one-third to one-half that of most steels.

Mechanical Plating

The copper flash coating is followed by the zinc spray coating in mechanical plating. While larger coatings are conceivable, commercial fasteners typically have a thickness of 2 mils (50 m). The coating has a density of around 0.45 oz/ft2/mil, compared to roughly 0.6 oz/ft2/mil for hot-dip galvanized coatings. In comparison to a mechanical coating, a hot-dip coating contains roughly 30% more zinc per unit volume.

Zinc Spraying (Metallizing)

With a specific gravity of 6.4, compared to 7.1 for zinc metal, the sprayed zinc coating is rough and slightly porous. As zinc corrodes in the environment, corrosion products tend to fill the holes. The kinetic energy of the sprayed zinc particles determines the coating adhesion mechanism, which is largely mechanical. There are no zinc-iron alloy layers present.

Metallizing effectively covers welds, seams, ends, and rivets, can provide coatings thicker than 10 mils (254 m), and can be applied in the shop or on the job. Operator experience influences coating consistency, therefore coating variance is always a possibility. Coatings on corners and edges may be thinner, and the method is ineffective for covering recesses and cavities.

Zinc Painting

Zinc-rich paints, either organic or inorganic, are applied to a dry film thickness of 2.5 to 3.5 mils (64 to 90 m). Epoxies, chlorinated hydrocarbons, and other polymers are used in organic zinc paints. Organic alkyl silicates are used a lot in inorganic zinc paints. Cathodic protection can only be achieved if the zinc dust concentration is high enough to provide electrical conductivity in the dry film.

Zinc Spray Gun Manufacturer in India

Ambica Enterprises is a Leading Manufacturer, Supplier & Exporter of Zinc Spray Gun, thermal Spray gun, metalizing gun, HVOF Gun, arc spray gun, flame spray gun, zinc spray gun, sand Blasting Machine, Shot Blasting Machine, Grit Blasting Machine, Shot Blasting Cabinet, Suction Blasting Cabinet, Sand Blasting Nozzle, Shot Blasting Room, abrasive media in India at a low price with the best quality for sale.