Thermal Spray Gun

Price Range : ₹ 45K - 6Lakh

Air Transport

Sea Transport

Land Transport

- Improved thin film process understanding and optimization

- Improve component administration life.

- A wide variety of components that operate in harsh settings where erosive forces like heat, corrosion, wear, and abrasion work together to shorten component life are covered with thermal sprayed coatings.

- Give a superior bond coat in a covering system.

- Utilize less costly substrate materials for parts, yet keep up superior surface properties.

4.5 Star Rating by our Precious Clients

- More Details

- Call Now

- Get Latest Price

![]()

Leading Supplier & Exporter

![]()

Trustseal Verified

![]()

ISO Certified

![]()

Manufacturer

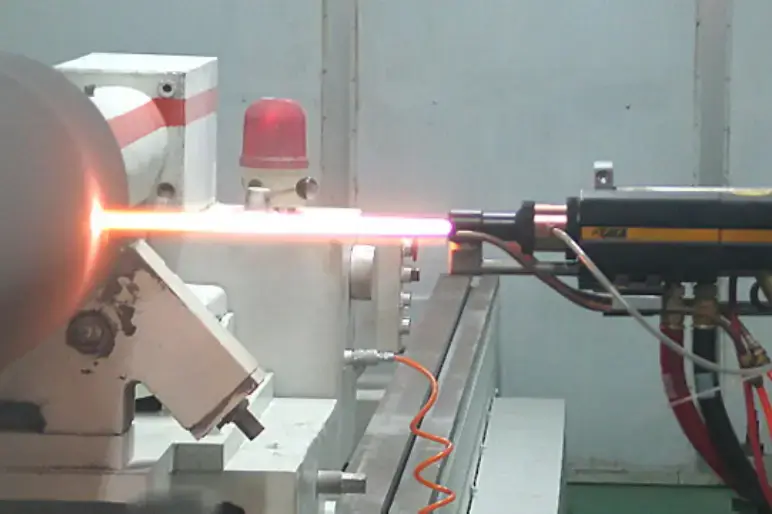

The use of a thermal spray Gun to improve surface properties is a cost-effective method. All popular thermal sprinkling techniques are supported, with options to fit your surfacings and other application elements such as run size, component scale, environmental considerations, and portability requirements. These guns are used to apply the media to the subjected material (rod, wire, powder).

Thermal Spray refers to a series of coating methods for applying metallic or nonmetallic coatings. Flame spray, electric arc spray, and plasma arc spray are the three main types of these techniques. The coating material (in powder, wire, or rod form) is heated to a molten or semi-molten condition using these energy sources. Process gases or atomization jets accelerate and propel the resulting hot particles toward a prepared surface. Following impact, a bond forms with the surface, producing a thickness increase and the formation of a lamellar structure. The thin splats are cooled at extremely fast rates, generally exceeding 106 K/s for metals.

Thermal Spray Coating

The thermal spray gun is an industrial coating process that consists of a heat source (flame or electric) and a coating material in a powder or wire form which is literally melted into small droplets and sprayed onto surfaces at large velocity. This “spray welding” method is known by several names including Plasma Spray, HVOF, Arc Spray, Flame Spray gun, and Metalizing gun. Thermal spray coating is typically utilized to metal substrates, but can also be applied to some plastic substrates. This type of coatings uniquely enhances and improves the performance of the component.

Types of thermal spray coating

There are various different types of processes used to apply a thermal spray coating. They are the following :

- Conventional flame spray

- Electric arc wire spray

- Plasma spray

- High-velocity oxy-fuel spray (HVOF).

- Flame Spray Gun

- Wire Flame Spray Gun

- Rod Spray Gun

- Powder Flame Spray Gun

- HVOF

- HVAF

- Arc Spray Gun

- Twin Wire Arc Spray Gun

Thermal Spray Coating Processes

Thermal spray is a general term used for a coating process in which the coating substance is burned or melted instantly by means of combustion, electric arc, or plasma, and together proposed by gases onto a ready substrate. It is a process in which elements, ceramics, and synthetics, starting as either fine particles or wires, are sprinkled onto a surface after being burned to their melting point by an electric arc or combustion flame. Flame spray, electric arc spray, and plasma arc spray are the three basic categories in which members of the thermal spray family of processes fall, each with a number of subsets. The following factors usually influence the choice of a thermal spray gun:

-

Coating material preference

-

Coating performance criteria

-

Cost-effectiveness

-

Part size and portability

Flame Spray Gun Process

Flame spraying includes low-velocity powder flame, rod flame, and wire flame processes and high-velocity processes such as HVOF and the detonation gun (D-Gun) process (D-Gun is a registered trademark of Praxair Surface Technologies Inc.).

Powder Flame Spray Gun

In the flame powder process, the powdered feedstock is aspirated into the oxyfuel flame, melted, and carried by the flame and air jets to the workpiece. Particle speed is relatively low (<100 m/s), and the bond strength of the deposits is generally lower than the higher velocity processes. Porosity can be high and cohesive strength is also generally lower. Except for lower melting point materials, which spray at substantially higher rates, spray rates are typically in the 0.5 to 9 kg/h (1 to 20 lb/h) range. Because of the flame impingement, the surface temperature of the substrate might reach dangerously high levels.

Wire Flame Spray Gun

The fundamental role of the flame in a wire flame spray gun is to melt the feedstock material. The molten material is then atomized and propelled toward the workpiece by a jet of air. For materials like stainless steel, spray rates range from 0.5 to 9 kg/h (1 to 20 lb/h). Lower melting point materials, such as zinc and tin alloys, spray at significantly faster rates than higher melting point materials. Because of the high energy input required for flame melting, substrate temperatures frequently range from 95 to 205 °C (200 to 400 °F). In most thermal spray processes, the feedstock material is melted with less than ten percent of the input energy.

Electric Arc Spray Gun Process

Two consumable wire electrodes attached to a high-current direct-current (dc) power supply are fed into the gun and meet, forming an arc between them that melts the wire tips in the electric arc spray gun process (also known as the wire arc process). A jet of air atomizes the molten metal and propels it toward the substrate. Because the entire input energy is used to melt the metal, the process is energy efficient. Spray rates are primarily determined by operating current and vary depending on the melting point and conductivity of the material.

Typical spray rates for copper- and iron-base alloys are 4.5 kilograms (10 lb)/100 A/h. Zinc is sprayed at a rate of 11 kilograms (25 lb) per 100 A/h. Because no hot jet of gas is directed toward the substrate, the temperature of the substrate can be extremely low. Electric arc spraying can also be done in a controlled-atmosphere chamber or with inert gases.

Plasma Arc Spray Gun Process

Air or atmospheric plasma arc spray gun is the colloquial name for the traditional plasma spray process (APS). Plasma temperatures in the powder heating zone vary from 6000 to 15,000 °C (11,000 to 27,000 °F), well exceeding any known material's melting point. A dc arc superheats an inert gas typically argon or an argon-hydrogen mixture to produce plasma. An inert carrier gas is used to deliver the powder feedstock, which is then propelled toward the workpiece by the plasma jet.

To keep substrate temperatures between 95 and 205 °C (200 and 400 °F), measures for cooling or controlling the spray rate may be required. Plasma spray guns in the commercial market range from 20 to 200 kW. As a result, spray rates are heavily influenced by gun design, plasma gases, powder injection schemes, and material properties, including particle size, dispersion, melting point, morphology, and apparent density.

Advantages of Thermal Spray Gun

Thermal spray Gun methods have the advantage of being able to manufacture coatings from a wide range of materials. Almost any substance that melts and does not decompose can be used. The capacity of most thermal spray techniques to apply coatings to substrates without significant heat input is a second major advantage.

As a result, materials with extremely high melting points, such as tungsten, can be used on finely machined, thoroughly heat-treated parts without affecting the part's characteristics or causing significant thermal distortion. The ability to take off and recoat worn or damaged coatings without affecting part qualities or dimensions is a third advantage.

Applications of thermal Spray gun

-

Process control equipment continues to progress (robotics, motion control, gas pressure technology, real-time sensors, and so on).

-

Improved nondestructive coatings testing and assessment methodologies

-

Improved thin film process understanding and optimization

-

Enhanced cold spray process interpretation and optimization

-

Thermal spray forming of near-net-shape components

-

Spray forming of high essential temperature (Tc ) superconducting oxide ceramics

-

CAD/rapid prototyping methods such as stereolithography

-

Diamond synthesis and testimony

-

Thin-film deposit via LPPS

-

Enhanced feedstock exhibition techniques and quality control

-

New materials (e.g., composites, nanophase materials, perovskites, and zirconates)

Ambica Enterprises is a manufacturer, supplier, and Exporter of Thermal Spray Gun coating, Flame Spray Gun, Tungsten Carbide Coating, Metalizing Gun, Metalizing Spray Gun, Arc spray gun, Sand Blasting machine, grit blasting machine, etc. at low price best quality.