Copper Spray Metalizing

The copper spray metalizing (copper spray gun) is used for a thermal spray of copper over the surface of the substrate. The copper coating thermal spray gun is used for coating after the sandblasting process. Before the copper spray metalizing with the copper thermal spray gun surface finishing is done with the sand blasting machine.

What is a Zinc Spray Gun?

The zinc spray gun is used for the coating process on the surface of the substrate to prevent rust. In a zinc spray gun, zinc and zinc alloys are sprayed over the surface of the component after melting it. To melt the zinc wire and zinc wire alloys oxygen and acetylene are used with compressed air.

Working of Aluminum Spray Gun

The aluminum spray gun is used for the coating process with aluminum wire on the surface of the substrate to avoid the risk of rust and oxidation. Aluminum wire is sprayed in an aluminum spray gun is sprayed across the surface of the component after melting it. In this process to melt, the aluminum wire oxygen and acetylene, or sometimes LPG gas is used with compressed air. Sometimes Oxygen and acetylene melt the aluminum wire and compressed air is used to atomize the molten metal or semi-molten metal on the surface of the substrate. In aluminum spray gun rollers are used to push and pull the wire in forward and backward direction.

Spare Parts of Flame Spray Gun

There are some spare parts used in a flame spray gun and Wire comes first in the siphon plug and then in the blasting nozzle, it completely holds the wire. The siphon plug should be cleaned occasionally. Wipe out the grooves and clean out the holes with the proper size wires from the cleaning wire kit. Do not wash the o-rings with a cleaning solvent. Examine them for damage and replace them if required. Do not stretch new o-rings more than necessary. Lubricate all o-rings before reassembling the siphon plug.

Use of Gas Flow Meter

The gas flow meter is a highly accurate and reliable instrument for regulating and measuring the flow of both oxygen and fuel gas in a manual powder and wire thermal & arc spray gun. It has precision needle valves which are actuated by adjustment knobs on the front panel that controls the movement of gas through the meter. Flow unit readout is provided in both Metric (NLPM) and U.S. Customary (SCFH) units.

What is Boiler Tube Coating?

Boiler Tube Coating is a must for increase the life of boiler tubes. The Thermal spray gun on boiler tube coating technology to give high-temperature wear & corrosion protection coating on the boiler tubes. A broad type of coating materials such as mild steel or other metals or alloys is available. Therefore a proper coating can be utilized on the tubes to combat the specific queries without changing the tube material.

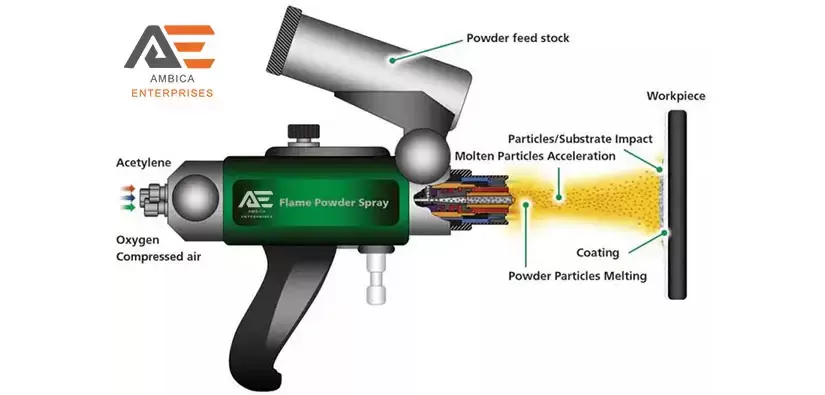

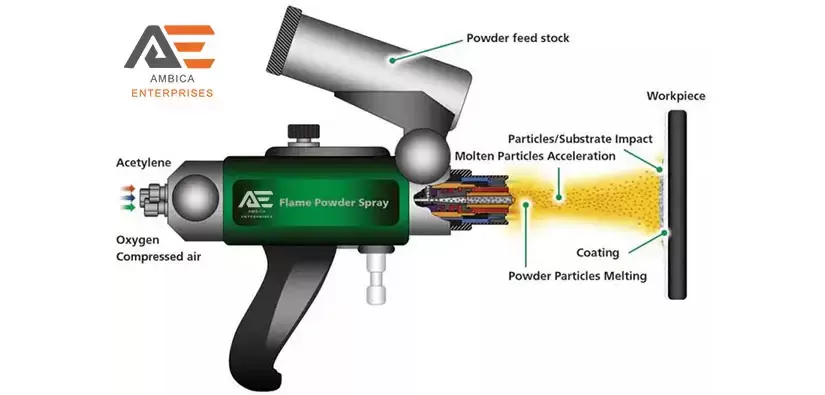

Working Behind Powder Flame Spray Gun

The Powder Flame Spray Gun process works a comparable technique as the Flame Wire Spray method, but that the wire flame spray gun feedstock is replaced by a powder. The main benefit of this method is that a much wider variety of materials (such as nickel or cobalt-based self Fixing composites or ceramic substances) can be easily treated into powder form providing a greater choice of coatings. Many compounds are difficult or cannot be presented in a wire form and for this purpose, it was produced.

Types of Flame Spray Gun

Flame spraying uses flame spray gun for coating. A thermal spray process variation in which the controlled explosion of a mixture of fuel gas, oxygen, and the powdered coating material is utilized to melt and propel the material to the workpiece. It includes low-velocity thermal spray powder, red, and wire flame processes and high-velocity processes.

-

The copper spray metalizing (copper spray gun) is used for a thermal spray of copper over the surface of the substrate. The copper coating thermal spray gun is used for coating after the sandblasting process. Before the copper spray metalizing with the copper thermal spray gun surface finishing is done with the sand blasting machine.

The copper spray metalizing (copper spray gun) is used for a thermal spray of copper over the surface of the substrate. The copper coating thermal spray gun is used for coating after the sandblasting process. Before the copper spray metalizing with the copper thermal spray gun surface finishing is done with the sand blasting machine. -

The zinc spray gun is used for the coating process on the surface of the substrate to prevent rust. In a zinc spray gun, zinc and zinc alloys are sprayed over the surface of the component after melting it. To melt the zinc wire and zinc wire alloys oxygen and acetylene are used with compressed air.

The zinc spray gun is used for the coating process on the surface of the substrate to prevent rust. In a zinc spray gun, zinc and zinc alloys are sprayed over the surface of the component after melting it. To melt the zinc wire and zinc wire alloys oxygen and acetylene are used with compressed air. -

The aluminum spray gun is used for the coating process with aluminum wire on the surface of the substrate to avoid the risk of rust and oxidation. Aluminum wire is sprayed in an aluminum spray gun is sprayed across the surface of the component after melting it. In this process to melt, the aluminum wire oxygen and acetylene, or sometimes LPG gas is used with compressed air. Sometimes Oxygen and acetylene melt the aluminum wire and compressed air is used to atomize the molten metal or semi-molten metal on the surface of the substrate. In aluminum spray gun rollers are used to push and pull the wire in forward and backward direction.

The aluminum spray gun is used for the coating process with aluminum wire on the surface of the substrate to avoid the risk of rust and oxidation. Aluminum wire is sprayed in an aluminum spray gun is sprayed across the surface of the component after melting it. In this process to melt, the aluminum wire oxygen and acetylene, or sometimes LPG gas is used with compressed air. Sometimes Oxygen and acetylene melt the aluminum wire and compressed air is used to atomize the molten metal or semi-molten metal on the surface of the substrate. In aluminum spray gun rollers are used to push and pull the wire in forward and backward direction. -

There are some spare parts used in a flame spray gun and Wire comes first in the siphon plug and then in the blasting nozzle, it completely holds the wire. The siphon plug should be cleaned occasionally. Wipe out the grooves and clean out the holes with the proper size wires from the cleaning wire kit. Do not wash the o-rings with a cleaning solvent. Examine them for damage and replace them if required. Do not stretch new o-rings more than necessary. Lubricate all o-rings before reassembling the siphon plug.

There are some spare parts used in a flame spray gun and Wire comes first in the siphon plug and then in the blasting nozzle, it completely holds the wire. The siphon plug should be cleaned occasionally. Wipe out the grooves and clean out the holes with the proper size wires from the cleaning wire kit. Do not wash the o-rings with a cleaning solvent. Examine them for damage and replace them if required. Do not stretch new o-rings more than necessary. Lubricate all o-rings before reassembling the siphon plug. -

The gas flow meter is a highly accurate and reliable instrument for regulating and measuring the flow of both oxygen and fuel gas in a manual powder and wire thermal & arc spray gun. It has precision needle valves which are actuated by adjustment knobs on the front panel that controls the movement of gas through the meter. Flow unit readout is provided in both Metric (NLPM) and U.S. Customary (SCFH) units.

The gas flow meter is a highly accurate and reliable instrument for regulating and measuring the flow of both oxygen and fuel gas in a manual powder and wire thermal & arc spray gun. It has precision needle valves which are actuated by adjustment knobs on the front panel that controls the movement of gas through the meter. Flow unit readout is provided in both Metric (NLPM) and U.S. Customary (SCFH) units. -

Boiler Tube Coating is a must for increase the life of boiler tubes. The Thermal spray gun on boiler tube coating technology to give high-temperature wear & corrosion protection coating on the boiler tubes. A broad type of coating materials such as mild steel or other metals or alloys is available. Therefore a proper coating can be utilized on the tubes to combat the specific queries without changing the tube material.

Boiler Tube Coating is a must for increase the life of boiler tubes. The Thermal spray gun on boiler tube coating technology to give high-temperature wear & corrosion protection coating on the boiler tubes. A broad type of coating materials such as mild steel or other metals or alloys is available. Therefore a proper coating can be utilized on the tubes to combat the specific queries without changing the tube material. -

The Powder Flame Spray Gun process works a comparable technique as the Flame Wire Spray method, but that the wire flame spray gun feedstock is replaced by a powder. The main benefit of this method is that a much wider variety of materials (such as nickel or cobalt-based self Fixing composites or ceramic substances) can be easily treated into powder form providing a greater choice of coatings. Many compounds are difficult or cannot be presented in a wire form and for this purpose, it was produced.

The Powder Flame Spray Gun process works a comparable technique as the Flame Wire Spray method, but that the wire flame spray gun feedstock is replaced by a powder. The main benefit of this method is that a much wider variety of materials (such as nickel or cobalt-based self Fixing composites or ceramic substances) can be easily treated into powder form providing a greater choice of coatings. Many compounds are difficult or cannot be presented in a wire form and for this purpose, it was produced. -

Flame spraying uses flame spray gun for coating. A thermal spray process variation in which the controlled explosion of a mixture of fuel gas, oxygen, and the powdered coating material is utilized to melt and propel the material to the workpiece. It includes low-velocity thermal spray powder, red, and wire flame processes and high-velocity processes.

Flame spraying uses flame spray gun for coating. A thermal spray process variation in which the controlled explosion of a mixture of fuel gas, oxygen, and the powdered coating material is utilized to melt and propel the material to the workpiece. It includes low-velocity thermal spray powder, red, and wire flame processes and high-velocity processes.