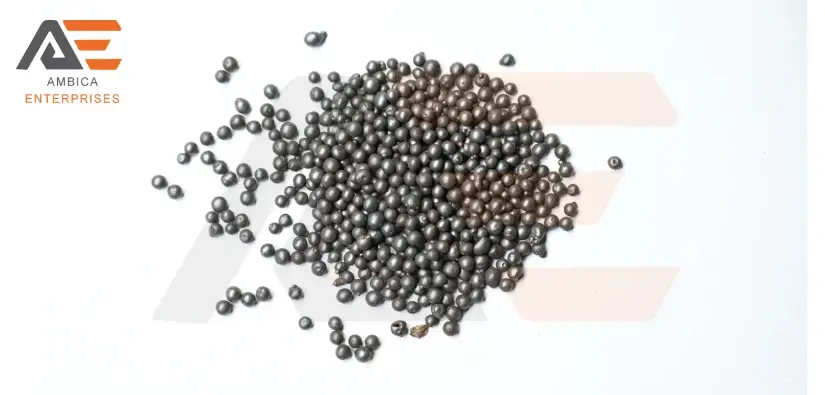

Steel Shot

Steel shot is a type of spherical projectile used in various industrial applications, such as surface preparation, shot peening, and metal cleaning. It is typically made from high-carbon steel wire, which is cut into small pieces and then molded into a spherical shape using a specialized machine.

Steel shot is often used as a substitute for traditional abrasives, such as sand, due to its superior hardness and durability. It is commonly used to remove rust, paint, and other coatings from metal surfaces, as well as to strengthen metal parts by inducing compressive stress through shot peening.

Steel shot is available in a range of sizes, from very fine to very coarse, and can be used with various types of equipment, such as abrasive blasting machines and centrifugal blasting wheels. It is also available in different hardness levels, which can be tailored to the specific application to achieve the desired results.

Steel Shot Abrasive

steel shot in India is commonly used as an abrasive in industrial applications. Its spherical shape and high hardness makes it an effective abrasive for cleaning, preparing, and strengthening metal surfaces.

When used as an abrasive, steel shot is typically propelled at high velocity onto the surface of the part to be cleaned or treated. The impact of the steel shot on the surface removes contaminants, roughens the surface, or induces compressive stress, depending on the application.

Steel shot abrasives are available in a range of sizes and hardness levels, allowing them to be tailored to specific applications. The size of the steel shot determines the level of aggressiveness of the abrasive action, with larger shot sizes producing a more aggressive abrasive effect. The hardness of the steel shot is also important, as it determines the durability and lifespan of the abrasive.

For more info about steel shot price visits our website.

Steel shot abrasives are commonly used in applications such as surface preparation, shot peening, and shot blasting. In each of these applications, the steel shot is used to remove surface contaminants, prepare the surface for further processing, or induce compressive stress in the metal part to strengthen it.

Steel Shot Application

Steel shot has a wide range of industrial applications due to its unique properties, such as hardness, durability, and spherical shape. Here are some of the most common applications of steel shot:

- Surface preparation: Steel shot is commonly used in surface preparation applications to remove rust, paint, and other coatings from metal surfaces. It is particularly effective for preparing surfaces for painting, powder coating, or other types of surface treatments.

- Shot peening: Steel shot is often used in shot peening machine applications to strengthen metal parts by inducing compressive stress. This process involves bombarding the surface of the metal part with steel shot, which creates small indentations on the surface and induces compressive stress that helps to resist fatigue and improve the life of the part.

- Metal cleaning: Steel shot is also used for cleaning metal parts, particularly those with intricate shapes or hard-to-reach areas. The spherical shape of the shot allows it to penetrate crevices and clean more effectively than other types of abrasives.

- Shot blasting: Steel shots can be used in shot blasting machine applications to clean or prepare surfaces for further processing. This process involves propelling the steel shot at high velocity onto the surface of the part to be cleaned or treated, which effectively removes surface contaminants or roughens the surface for better adhesion.

For more information about steel shot supplier visits our website.

Advantages of using steel shot

There are several advantages of using steel shot in industrial applications, including:

- High hardness: Steel shot is a very hard material, which makes it highly effective for abrasive sand blasting machine applications. Its hardness allows it to remove surface contaminants, prepare surfaces for further processing, and induce compressive stress in metal parts.

- Durability: Steel shot is also very durable, which means that it can be used for extended periods without losing its abrasive effectiveness. This reduces the need for frequent replacement and helps to keep costs down.

- Spherical shape: Steel shot has a spherical shape, which allows it to penetrate crevices and hard-to-reach areas more effectively than other types of abrasives. This makes it highly effective for cleaning complex or intricate metal parts.

- Reusability: Steel shot can be reused multiple times, which makes it a cost-effective abrasive option. After being used, it can be cleaned and reconditioned for further use, reducing waste and saving money.

- Versatility: Steel shots can be used in a wide range of industrial applications, from surface preparation to shot peening to metal cleaning. Its versatility makes it a valuable tool for many different industries, including automotive, aerospace, and manufacturing.

For more infomation about steel grit visits our website.

Overall, the high hardness, durability, spherical shape, reusability, and versatility of steel shot make it a highly effective and cost-efficient abrasive for many industrial applications.

Also Check - Shot Blasting Machine for Steel Industry