Steel shot blasting media is a type of abrasive media used for shot blasting machine applications. Shot blasting is a process that involves propelling abrasive media at high velocity onto the surface of a metal part to clean or prepare it for further processing.

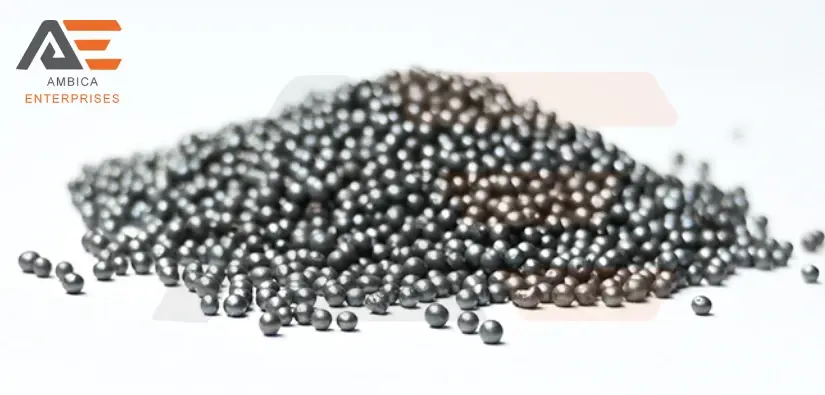

Steel shot blasting media is made from high-carbon steel wire that has been cut into small pieces and molded into spherical shapes. The spherical shape of the steel shot allows it to penetrate crevices and clean more effectively than other types of abrasive media.

Steel shot blasting media is available in a range of sizes and hardness levels, which can be tailored to the specific application. Larger shot sizes produce a more aggressive abrasive effect, while smaller sizes produce a smoother finish.

One of the advantages of steel shot blasting media is its durability. Steel shot in India is a very hard material that can be used for extended periods without losing its abrasive effectiveness. This reduces the need for frequent replacement and helps to keep costs down.

Steel shot blasting media is commonly used in applications such as surface preparation, shot peening, and metal cleaning. It is particularly effective for preparing surfaces for painting, powder coating, or other types of surface treatments.

Overall, steel shot blasting media is a highly effective and versatile abrasive that can be used in many different industrial applications. Its hardness, durability, and spherical shape make it an ideal choice for shot blasting and other abrasive processes.

Steel Shot Blasting

When certain surface finishes are required, steel shot blasting is a procedure used to perfect or clean steel. Steel shot is used in almost every industry imaginable. Massive construction, shipbuilding, rail, and auxiliary manufacturing are examples of these.

In various stages of primary metal production, blast cleaning with steel shot is critical. The various types and sizes of steel shot produce an outstanding outcome on the metal surface. Because of its toughness and endurance, it is one of the most cost effective because it can be recycled hundreds, if not thousands, of times.

Larger steel shot blasting thoroughly cleans a rougher surface. Both wheel blast and air pneumatic systems are utilized to accelerate steel shot on the surface.

For more information about sand blasting helmet visits our website.

Advantages of Steel Shot Blasting

- It produces a great polish on the metal surface.

- Very long-lasting

- Cost-effectiveness and recyclability

- Air power and wheel blast systems can both be utilized.

- Provide a pristine surface by removing surface contaminants.

For more information about the sand blasting machine visits our website.

Features of steel shot

Here are some of the key features of steel shot blasting media:

- Hardness: Steel shot blasting media is made from high-carbon steel wire, which gives it a high level of hardness. This allows it to effectively remove surface contaminants and prepare surfaces for further processing.

- Spherical shape: Steel shot blasting media has a spherical shape, which allows it to penetrate crevices and hard-to-reach areas more effectively than other types of abrasive media. This makes it highly effective for cleaning complex or intricate metal parts.

- Durability: Steel shot blasting media is very durable and can be used for extended periods without losing its abrasive effectiveness. This reduces the need for frequent replacement and helps to keep costs down.

- Reusability: Steel shot blasting media can be reused multiple times, which makes it a cost-effective abrasive option. After being used, it can be cleaned and reconditioned for further use, reducing waste and saving money.

- Range of sizes: Steel shot blasting media is available in a range of sizes, from fine to coarse. This allows it to be tailored to specific applications, from surface preparation to shot peening to metal cleaning.

- Corrosion resistance: Steel shot blasting media is resistant to corrosion, which makes it an ideal choice for marine applications or other environments where corrosion is a concern.

- Consistency: Steel shot blasting media is manufactured to precise specifications, which ensures a consistent size, shape, and hardness. This helps to ensure a consistent abrasive effect and reduces variability in the process.

For more information about thermal spray gun visits our website.

Overall, the high hardness, durability, spherical shape, reusability, range of sizes, corrosion resistance, and consistency of steel shot blasting media make it a highly effective and cost-efficient abrasive for many industrial applications.