What is HVOF Tungsten Carbide Coating?

Among the most favorable options are high velocity oxygen fuel spray, or HVOF tungsten carbide coating. Comprehensive interpretation testing & an increasing numeral of prosperous commercial usefulness are establishing implementation advantages of HVOF tungsten carbide coatings for a type of flying engines & airframe elements. These contain aircraft landing gear, hydraulic actuators, jet engine bearings & bearing housings, turbine shafts, & actually several dynamic elements like helicopter drive trains & propeller groups. Ambica Enterprises provides all types of thermal spray guns for thermal spray coating.

Capable of delivering enhanced wear, impact, & fatigue resistance, as well as similar or more useful rust resistance, these unique coatings are substituting inaugurated hardened chromium coatings in numerous challenging applications.

For More details about HVOF Gun Price visit our website.

HVOF Tungsten Carbide Coating Process

furthermore, due to the implementation benefits that HVOF tungsten carbide coatings are capable of delivering in front of retaliating working states, HVOF tungsten carbide coating process is easier to carry out than established electrolytic chrome plating baths. In fact, a type of previously published technology assessments (many of them joint tasks between private & military sectors) have concluded that HVOF thermal spray coating of tungsten carbide is a viable technology for hard chrome replacement. To date, comprehensive lab & prototype testing, & increasingly far-reaching commercial experience, keep indicated comparable or superior performance to chromium plating in terms of wear, corrosion, & heat resistance; application feasibility; and general lifecycle costs & process economics.

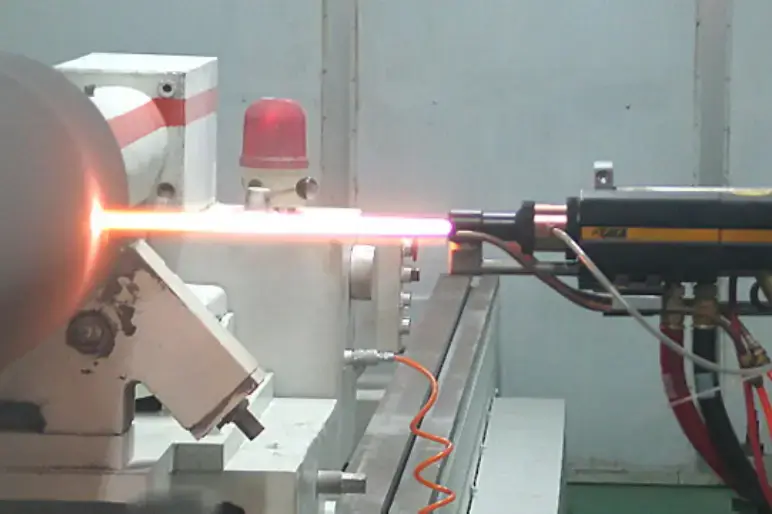

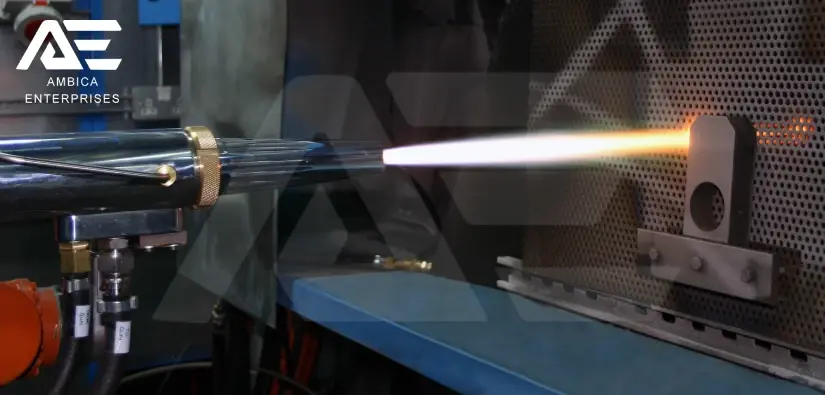

HVOF coatings are deposited by thermal spray. During this process, fuel gas & oxygen are pre-mixed, & provided at high-pressure into a discharge enclosure, where they burn to have a burning, high-pressure gas stream. Tungsten carbide powder bits are infiltrated directly into this combustion area of gun underneath automatic control. As high-velocity gas stream (containing semi-molten powder ) is supervised toward substrate, the impact also deposition of the particles on surface assembles a wide, uniform coating, typically with< 1% porosity, an oxide content of < 1%, & a bond strength in excess of 80 MPa (10 ksi). HVOF coating process is maintained release in a spray booth, with a robotic apparatus.

For more information about HVOF Coating Process visit our website.

The HVOF deposition process is quicker than established chrome plating. Characteristic tungsten carbide coatings are applied in 1 hour or 2, versus 24 hours or more needed for tough chrome plating. Even, unlike toughchrome coatings, HVOF tungsten carbide coating doesn't experience hydrogen embrittlement, therefor time & price needed for embrittlement-relief treatment are stopped.

the macrohardness of HVOF tungsten carbide coating is greater than 70 Rc (Rockwell scale), compared escorted by standard values of 60 to 70 Rc for hardened chrome plating. Microhardness values for the tungsten carbide coating are on order of 1050 DPH 300 (Diamond Pyramid Hardness), compared escorted by values of 750 to 850 DPH that is typical of hardened chrome plate.

HVOF tungsten carbide coatings are already recovering multiple landing gear & airframe parts. For instance, Engelhard involves high velocity oxygen fuel spray or HVOF tungsten carbide coating on a broad collection of parts for both military also commercial aircraft, including landing gear & actuators.

Benefits of HVOF Tungsten Carbide Coating

- Heightened Bond Strength

- Lower Residual Pressure

- Lowly Porosity (Typically <0.5%)

- Heightened Wear Resistance

- FineTungsten Carbide Rust Resistance established on binder chemistry

Ambica Enterprises offers all type thermal spray coating gun, metalizing guns, zinc spray guns, flame spray gun, thermal spray powder, tungsten carbide powder, ceramic powder, molybdenum powder, abrasive blasting machine, spare parts, dust collectors, abrasive media, and mineral powder, etc.