HVOF Gun

Price Range : ₹ 2Lakh - 10Lakh

Air Transport

Sea Transport

Land Transport

- Hydro Power – Pelton, Seat, Runner, Francis turbine, etc.

- Thermal Power – ID Fan, Barrel, Boiler tube, etc.

- Aerospace – Landing gear.

- Paper Industry – Rolls.

- General – Shafts, Bearing, Rollers, Rings.

- Valves – Ball Valve, Gate Valve, etc.

4.5 Star Rating by our Precious Clients

- More Details

- Call Now

- Get Latest Price

![]()

Leading Supplier & Exporter

![]()

Trustseal Verified

![]()

ISO Certified

![]()

Manufacturer

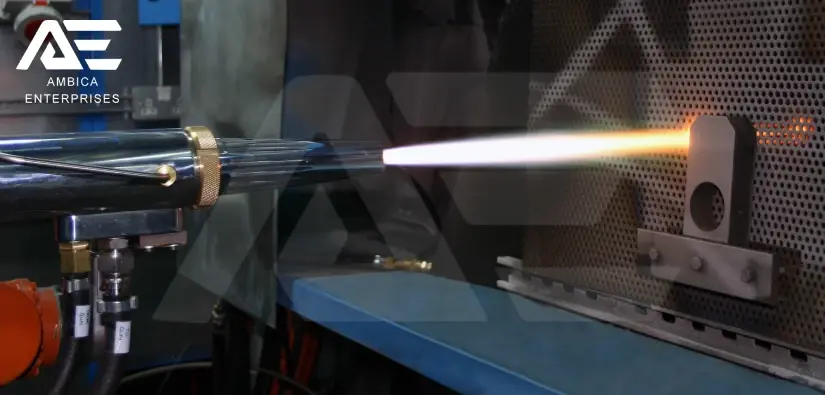

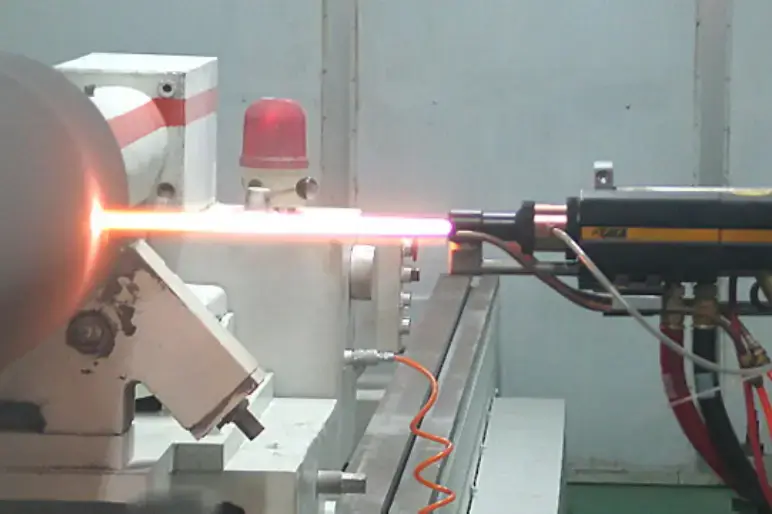

HVOF Gun (High Velocity Oxygen Fuel Gun) instruments are a subdivision of the flame spray gun. There live two distinctions in middle of HVOF as well as ordinary flame spray. through warm & activated powdered coating material, HVOF Gun employs a narrow discharge & a broad nozzle. HVOF Gun devices are characterized by employing hypersonic gas velocities, which are larger relative to MACH 5. The most significant velocities afford kinetic energy which enables the provision of coatings that are too thick & extremely well attached to the as-sprayed status. HVOF Coating process with an HVOF Gun needed an extremely high velocity. Before affecting the substrate, this high velocity is utilized to drive the particles to supersonic speeds. High explosion pressure & great gas also particle velocity result in lofty coating grade in HVOF coating process. There are two kinds of HVOF guns driven by fuel type like gaseous or liquid in nature.

HVOF Spray Gun

The HVOF (High Velocity Oxygen Fuel spray gun) Thermal Spray gun process is equal to flame powder spray gun, accompanied by exception that it existed designed to carry exceptionally lofty spray acceleration. There is a variety of HVOF guns available, each with its own method of gaining lofty speed spraying. A high-pressure water-cooled HVOF flame chamber with a long nozzle is one way. Fuel (kerosene, acetylene, propylene, also hydrogen) also oxygen live equipped into square, where discharge delivers a burning, high-pressure flame that is propelled from top to bottom a nozzle at a lofty acceleration. Powder is basically provided at lofty pressure from nozzle's center.

Specification of HVOF Spray Gun

|

Internal Coating Diameter |

160 mm Minimum |

|

Spraying Angles |

45° & 70° |

|

Net Weight |

5 kg approx. |

|

Spray Rate |

60 gm/min maximum |

|

HVOF Coating Thickness |

2.0 mm maximum |

|

HVOF Carbide Powder |

Particle size +5 -30 microns |

|

Gas Velocity |

550 – 750 m / s |

|

Cooling Capacity |

90 kW |

|

Power in Flame |

200 kW |

|

Combustion Chamber Pressure |

6-8 bar |

|

Exhaust Flow (Min.) |

15,000 m3 / hr |

|

Oxygen |

17– 20 bar 1100 nlpm |

|

Nitrogen (Carrier Gas) |

8 – 10 bar 20 nlpm |

HVOF Coating Process

After a thorough review of the literature, two types of HVOF coating process powders, (1) WC-12CO and (2) Cr3C2NiCr, were chosen for the discharge Spray Coating Process also the High Velocity Oxygen Fuel Spray Coating Process. HVOF Gun is engaged for the coating process to prevent the surface of the material from rusting after surface preparation with the usefulness of an abrasive blasting machine. The indicated coatings contain good bond strength also wear resistance, according to research publications.

Tungsten Carbide Cobalt (WC-12CO): Tungsten Carbide Cobalt powder creates exceptionally dense also homogenous coatings with excellent abrasive wear resistance when sprayed using the Detonation Spray technique. Ambica Enterprises provides Tungsten Carbide powder, ceramic powder, and molybdenum powder, The powder is sintered & agglomerated, with a particle size of -45+20 microns.

Chromium Carbide-Nickel Chromium Powder (Cr3C2NiCr): When sprayed utilizing the Detonation Spray technique, Chromium Carbide & Nickel Chromium powder generate coatings that are extremely hard, dense, also well-bonded. For resistance to feeling uneasy wear also abrasive particle oxidation, a Chromium Carbide & Nickel Chromium coating is advised. The powder is sintered & agglomerated, with particle sizes ranging from 10-45 µm.

Benefits of HVOF Gun

- Low porosity (<1%)

- Higher bond strength (>10000 psi)

- Uniform repeatability

- Low operating cost

- Higher particle velocities

- Stable deposition rate

- Controlled coating thickness

- Safety interlocks

HVOF Gun Manufacturer in India

Ambica Enterprises is a top manufacturer, supplier & Exporter of Hvof spray gun ( High Velocity Oxygen Fuel spray gun ), metalizing gun, aluminum spray gun, zinc spray gun, 5 PM-II powder flame spray gun, Twin wire arc spray gun, thermal spray powder, thermal spray wire, powder feeders MPF-3350, thermal spray booths, Sand Blasting Machine, dustless and airless shot blasting machine, Internal pipe blaster tools, Sand Blaster Cabinet, Bench Top Sand Blasting Cabinet, sand Blast Nozzle, Blast Room System, abrasive media in India at a lower price with the finest quality for sale.