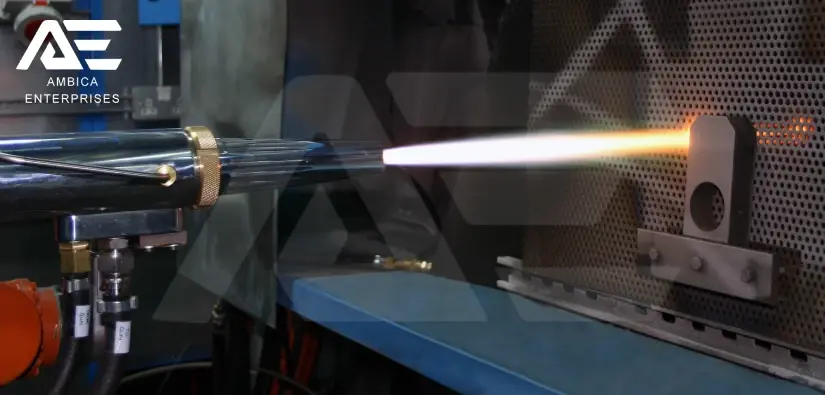

In the aerospace sector, HVOF (High-Velocity Oxygen Fuel) coating is frequently utilized to provide protective coatings to components like landing gear legs. Critical parts of an aircraft that experience severe wear and stress during takeoff, landing, and taxiing are the landing gear legs.

Because they come into touch with runways, debris, and other surfaces, landing gear legs are prone to abrasive forces and wear. The wear resistance of the landing gear legs can be greatly improved by HVOF coatings, which are frequently comprised of materials like tungsten carbide. As a result, they last longer and require less maintenance and replacements overall. Aircraft frequently operate in a variety of environmental settings, subjecting the legs of the landing gear to dampness, chemicals, and corrosive substances. The structural integrity of the landing gear legs can be preserved using HVOF coating, which can act as an efficient barrier against corrosion.

As the airplane touches down during a landing, impact pressures are applied to the landing gear legs. HVOF coatings can aid in absorbing and dispersing these impact forces, reducing harm to the aircraft's legs and general structure. The thermal insulation capabilities of HVOF coatings can aid in controlling temperature variations during airplane operations. This can be crucial for avoiding overheating or sudden cooling that can impair the functioning of the landing gear.

Advantages of HVOF coating for Landing Gear Legs

The fatigue resistance of HVOF coating for landing gear legs can be improved via HVOF coatings, enabling them to tolerate repeated loading cycles without cracking or failing. Longer intervals between maintenance and inspections may result from coating the legs of the landing gear with HVOF materials. As a result, there are fewer operational hiccups and maintenance expenses. HVOF coatings can be applied in the form of thin, dense layers, which aids in preserving the aircraft's total weight. This is essential for aircraft design since weight minimization has a direct influence on the aircraft's performance and fuel economy. HVOF coatings offer controlled and uniform deposition, guaranteeing uniform coating thickness and quality throughout intricate landing gear leg geometries.

HVOF coatings can provide defense against the elements, such as UV rays and severe weather, which can damage the surface finish of landing gear legs. HVOF coatings can enhance the look of the landing gear legs in addition to their practical advantages, adding to the aircraft's overall aesthetic appeal. In the aircraft sector, HVOF coatings are essential for preserving the strength and efficiency of landing gear legs. The operational environment of the aircraft, the kind of landing gear system, and the materials used to create the landing gear will all affect the specific choice of coating material and process parameters.

Applications of HVOF coating for Landing Gear Legs

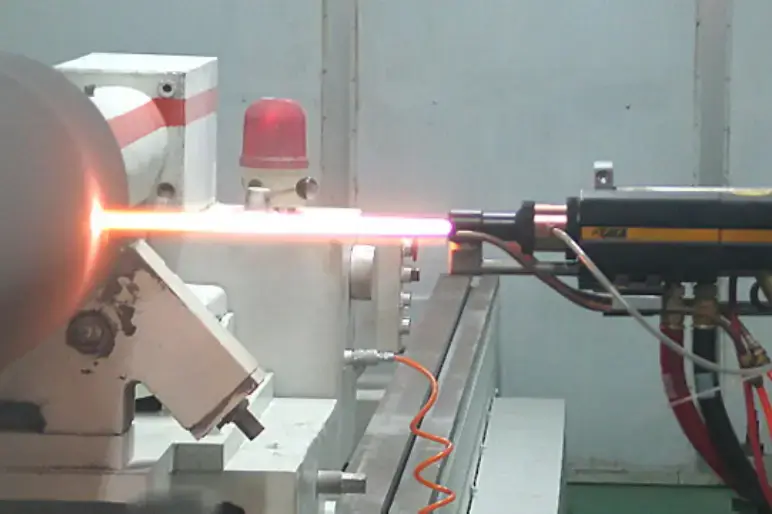

The main landing gear struts, which sustain the weight of the aircraft during takeoff and landing, can be coated with HVOF. The wear resistance, fatigue resistance, and corrosion protection of the struts are improved by these coatings, assuring their longevity and ideal performance. The nose landing gear struts can also gain from HVOF coatings, much as the main landing gear struts. The coatings reduce impact and wear during landings, particularly for aircraft that touch down nose-first. During takeoff, landing, and taxiing, the pistons inside the landing gear struts frequently experience compression and decompression. These pistons' HVOF coatings increase their resistance to wear and fatigue, extending their useful life.

Legs of landing gear may have a variety of retractable parts and systems. These components' resistance to abrasion, corrosion, and mechanical stress is increased when coated with HVOF materials, assuring dependable operation. on lessen impact forces during landings, Thermal spray coating can be applied on landing gear legs' shock-absorbing parts. The coatings increase the capacity of the shock absorbers to absorb and disperse energy, lowering stress on the aircraft structure. HVOF materials can be used to coat bearings and bushings in landing gear assemblies to lessen friction, wear, and galling danger. This results in increased operating effectiveness and less need for maintenance. Reliable operation is required from the systems in charge of retracting and deploying the landing gear. HVOF coatings can make these mechanisms more resistant to wear, ensuring they function.

Landing gear legs are shielded from corrosion-causing environmental elements such moisture, salt, and chemicals by HVOF coatings. For further structural integrity and corrosion and wear resistance, wheel well components including brackets and support structures can be coated with HVOF materials. Some HVOF coatings also offer the added advantage of reducing friction and impact noise, making for a quieter and more pleasant flight.