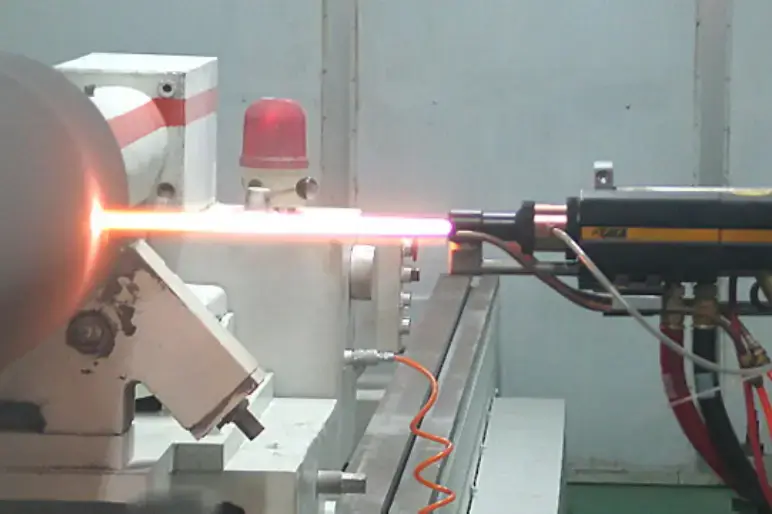

Thermal Spray Machine and Coating Process

The thermal spray machine is a cost-effective equipment for improving surface characteristics. We support all popular thermal sprinkle processes, with choices to suit your surfacings and all other application elements.

Portable Sandblasting Machine Price in IndiaA portable sandblasting machine, as mentioned in the name, means that you can move this machine from one place to another easily. Sandblasting Machines, are used for blasting cleaning.

Shot Blasting Machine in India

A shot blasting machine uses mechanical acceleration to control the flow or stream of small metal beads as they are forcedly pushed against a surface.

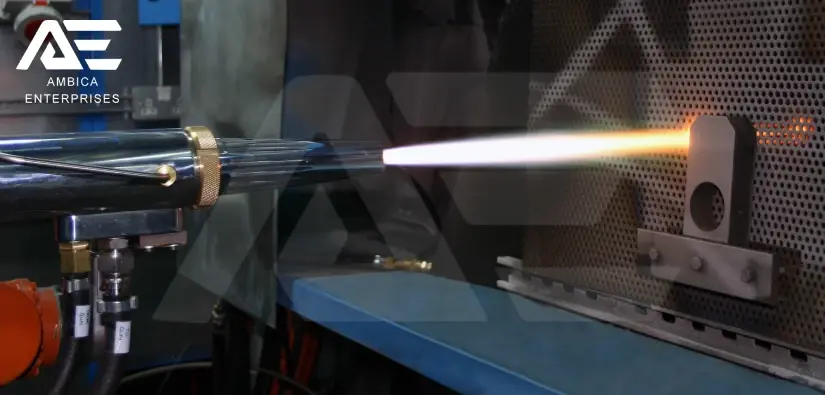

Tungsten Carbide Thermal Spray Coating

tungsten carbide thermal spray coating is a widely utilized coating material for a wide range of products in many different sectors. Equal amounts of carbon atoms and tungsten atoms make up tungsten carbide. With twice the density of steel, it is almost twice as strong nearly halfway between that of lead and gold. The (high-velocity oxy fuel) HVOF tungsten carbide coating forms an instant bond with the substrate upon application, offering exceptional wear resistance and bond strength.

Belt Type Shot Blasting Machine

A bunch of smallish elements & thin-wall castings, ceramics, delicate iron & aluminum alloy castings, & various job piece surface cleaning applications utilize belt type shot blasting machines. Carefully arranging multiple smallish jobpieces subsequently to severally other on a wire mesh belt can improve machine output.

Small Lapping Machine

Small lapping machine are handy, tiny, and typically manufactured for smaller workpieces and applications. They are also referred to the benchtop or tabletop lapping apparatus.

Granite Engraving Machine Price

Granite engraving machine price can differ widely based on several elements, including the kind of machine, its features, & specifications of granite engraving machine in India.

HVOF Coating for Landing Gear Legs

In the aerospace sector, HVOF (High-Velocity Oxygen Fuel) coating is frequently utilized to provide protective coatings to components like landing gear legs.

HVOF Tungsten Carbide Coating

HVOF Tungsten Carbide coatings are deposited by thermal spray. During this process, fuel gas & oxygen are pre-mixed, & provided at high-pressure into a discharge enclosure, where they burn to have a burning, high-pressure gas stream. Tungsten carbide powder bits are infiltrated directly into this combustion area of gun underneath automatic control. As high-velocity gas stream (containing semi-molten powder ) is supervised toward substrate, impact also deposition of the particles on surface assembles a wide, uniform coating, typically with< 1% porosity, an oxide content of < 1%, & a bond strength in excess of 80 MPa (10 ksi). HVOF coating process is maintained release in a spray booth, with a robotic apparatus.

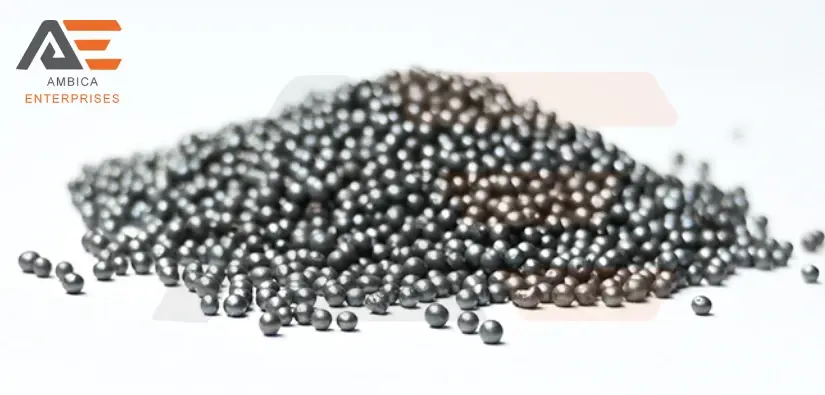

Steel Shot Blasting Media

Steel shot blasting media is a type of abrasive media used for shot blasting applications. Shot blasting is a process that involves propelling abrasive media at high velocity onto the surface of a metal part to clean or prepare it for further processing.