Steel Shot

Price Range : ₹ 65 /kg - 100 /kg

Air Transport

Sea Transport

Land Transport

- Steel shot abrasive is widely utilized for shot peening and shot blasting.

- Cast steel is shot-blasted.

- Removal of sand.

- Steel shot media is used for surface preparation.

- Steel shot blast media is used for scale reduction etc.

4.5 Star Rating by our Precious Clients

- More Details

- Call Now

- Get Latest Price

![]()

Leading Supplier & Exporter

![]()

Trustseal Verified

![]()

ISO Certified

![]()

Manufacturer

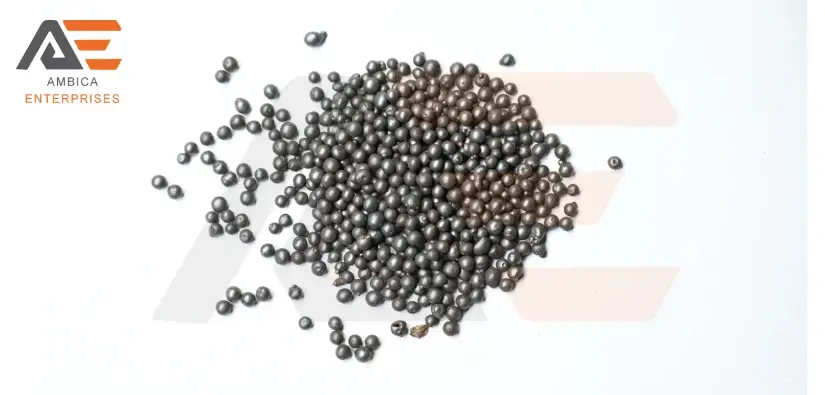

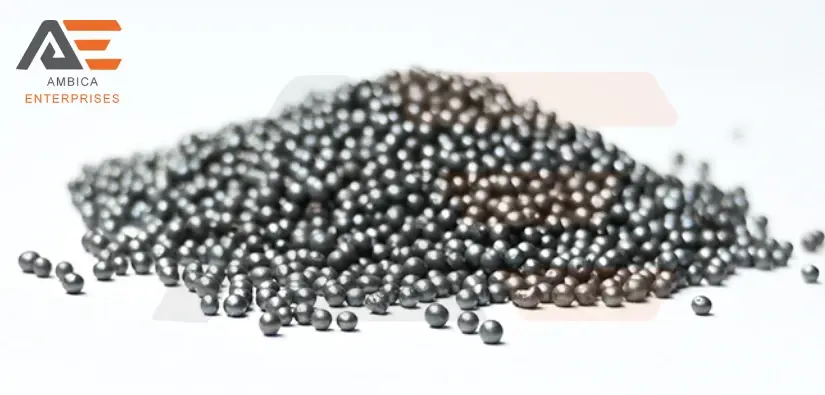

Steel shots

Steel shot Beads are a spherical product of hypereutectoid steel within a fully heat-treated situation. Steel shot is the uniform structure of finely tempered martensite that provides optimal resilience and resistance to fatigue. Steel Shots are the optimal abrasive for the bulk of wheel blast applications. Its durability and resistance to impact fatigue give maximum cleaning efficiency at the foremost economical cost. Ambica Enterprises provide all types of abrasive media like steel shot blast media, glass beads, copper slag, Aluminum oxide, plastic media, walnut shell, garnet sand, etc.

Steel Shot Blast Media

Steel Shot blast media helps in removing old paint, rust, or any quiet containment from the surface of the substrate and supplies an excellent surface that is freed from defects. Steel shot in India is used for surface preparation in order that the surface is often prepared for further operations like painting and thermal spray coating.

Steel Shots Size is available in several sizes and varieties which provides a perfect choice for use within the operation of shot blasting machine. It is present in several sizes and in shot blasting machines with compressed gas sizes depending upon the blasting nozzle. If the size is large then thesand blasting nozzle size nozzle is often blocked and no blasting is completed. In the shot blasting machine both portable shot blasting and shot blasting cabinet size of the nozzle, it depends upon the compressed gas availability. Steel Shots Size is robust and sturdy in nature, in order that they are considered to be the foremost economical abrasives. Steel shot is a blasting media that may be used easily in both wheel blast and air-powdered systems.

Ambica Enterprises is the leading steel shots manufacturer & supplier of steel shot in India. steel shot price can vary depending on a number of factors, including the size and quality of the shot, and the quantity purchased.

Specifications of Steel Shot

| Steel shots size | 0.8-2 mm |

| Packaging Size | 50 Kg |

| Usage/Applications | Shot Blasting |

| Shape | Round |

| Material | Steel shots |

Characteristics of steel shot beads

Chemical composition:

C ≥ 0,85%

P ≤ 0,05%

S ≤ 0,05%

Hardness:

450 – 535 HV (46 - 51 HRC) tolerance 60HV ( 2 HRC)

Advantages of Steel Shot media

- Media with a long shelf life.

- Produces low dust.

- May be reused numerous times.

- Very strong media.

- The finished product has a smooth and polished surface.

Steel Shots Size

| Steel Shots | Steel Shots Size |

| S70 | 0.18 - 0.35 |

| S110 | 0.30 - 0.50 |

| S170 | 0.42 - 0.71 |

| S230 | 0.59 - 0.84 |

| S280 | 0.71 - 1.00 |

| S330 | 0.84 - 1.19 |

| S390 | 1.00 - 1.41 |

| S460 | 1.19 - 1.68 |

| S550 | 1.41 - 2.00 |

| S780 | 2.00 - 2.80 |

| S930 | 2.36 - 3.35 |

Steel Shots Manufacturer in India

Ambica Enterprises is the best Steel Shots manufacturer in India. we provide the best quality to our customers at a low price. steel shot price depends on different factors. Steel shot price depends on the Steel shot Size & durability of steel shot in India. and Steel shot price also relies on the quality and quantity of steel shot abrasive. we also provide Sand blasting machine, abrasive shot blasting machine, sand blasting safety equipment, automatic sand blasting machine, Grit Blasting Machine, thermal spray gun, thermal spray wire, thermal spray powder, shot blasting machine price all over the world with the best quality. we are the best portfolio for abrasive media like steel shot, steel grit, quartz sand, copper slag, glass beads, plastic abrasive, aluminum oxide, and stainless steel shot at the best price in India.

Frequently Asked Questions (FAQ's)