Plasma HVOF Spray Gun

Price Range : ₹ 2Lakh - 10Lakh

Air Transport

Sea Transport

Land Transport

- The plasma spray gun is used for Thermal Barrier Coatings

- In Erosion- and Wear-Resistant Coatings

- In Corrosion-Resistant Coatings

- Electronic Applications: Plasma spray guns focus on protective coatings rather than functional such as dielectric, conductive, luminescent, and bioactive coatings.

- Other Smart Coatings: Self-healing coatings are in demand in multiple areas due to their ability to repair cracks and defects within coatings without any external intervention, extending their service time.

5 Star Rating by our Precious Clients

- More Details

- Call Now

- Get Latest Price

![]()

Leading Supplier & Exporter

![]()

Trustseal Verified

![]()

ISO Certified

![]()

Manufacturer

A plasma plume is employed as a high-enthalpy source in a plasma spray gun, whereas thermal energy is created from fuel combustion in the presence of oxygen in an HVOF Spray gun. Plasma spray has more thermal energy than HVOF spray, which aids in the melting of feedstock powder. Because kinetic energy of the raw material powder is larger in HVOF spray than in plasma spray caused by the supersonic acceleration of the flame, generated splats are thinner, and the created coatings are denser & better adherent than in plasma spray. The plasma source gas can be accommodated according to coating needs, like argon, a combination of argon and hydrogen, or argon, hydrogen, and nitrogen. HVOF guns may run on a variety of fuels, including kerosene, hydrogen, ethylene, and propylene. Most HVOF guns feature axial (parallel to the gas flow) feedstock injection, which permits particles to stay in contact with the warmness source for extended periods of time. In axial injection, a greater interchange of kinetic & thermal energy boosts deposit efficiency. Due to coming in touch escorted by the warmth conception for a shorter amount of time, feedstock infiltrated radially (perpendicular to the gas discharge) into plasma plume or flame experiences inadequate melting and speed.

The material to be deposited is infiltrated toward the plasma jet, whichever originates through a plasma spray gun, during plasma spray coating process. The material is liquefied & driven in connection escorted by a substrate in the spray, which contains a temperature of 10,000 K. The molten bead flattens, hardens quickly, & creates a deposit there. HVOF tungsten carbide coating can be as wide as 12 mm (1/2′′). It is generally utilized to spread wear & rust-resistant coatings on materials like ceramic also metallic coatings. Powders commonly used contain WC-Co, CrC, MCrAlY, & alumina. The procedure has proven to be particularly effective for spreading cermet materials (WC-Co, for example) & further erosion-resistant alloys (stainless steels, nickel-based, aluminum, hydroxy apatite for medical implants, and so on). Plasma/HVOF spray guns and systems are available from Alloy Coating Supply.

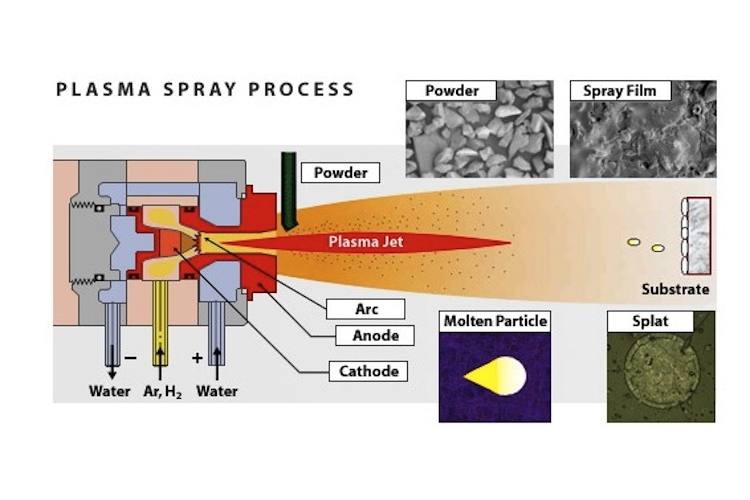

Plasma Spray Process

The warmness source is a plasma arc & the material scattered is a powder (ceramic, & metal) & moves through a plasma jet. Plasma is a phrase employed to define gas that contains existed introduced to a similar eloquent temperature alike it ionizes & evolves electrically conductive. During Plasma spray process, the plasma is made by an electric arc igniting enclosed by nozzle of a plasma spray gun & the arc gas is developed toward a plasma jet like it appears among nozzle. Powder bits are infiltrated & caught up in this jet locus they decompress & then hit exterior at a heightened speed to make an extraordinarily adhesive coating. The workpiece stays calm by reason of the plasma is confined to the gun.

Plasma Spray Coating

Plasma spray coating likewise helps contain another kind of erosion, i.e., hot erosion. It is prevalent in thermal barrier coatings when molten deposits from contaminants in the fuel like sodium, sulfur, vanadium, lead, & phosphorus drop on coatings. During discharge, these contaminants oxidize & form a strong acidic or alkaline molten oxide, deteriorating the ceramic also metallic parts of the thermal barrier coating system through particular leaching of the stabilizer from zirconia, resulting in degree modification and therefore volume changes ~3-5% upon cooling. The rust resistance of thermal spray gun coatings could be improved either by altering the coating architecture or incorporating certain oxygen-active elements into the coating. Usually, higher porosity is selected in TBCs due to better strain tolerance & lower thermal conductivity, but it is not beneficial for erosion & hot corrosion resistance because of the infiltration of molten salts & other impurities into the thermal barrier coating system.

Plasma & HVOF coatings are additionally generally utilized to spread engineering coatings. In easy words, the coatings produced by plasma & HVOF are of more elevated grade, bond strength, and density than flame or arc coatings but are costlier & slower to apply. Hence, the reason flame & arc spray gun coatings are more widely utilized for erosion shields of more extensive structures. There is a numeral of applications, for instance, heightened temperature mixed with heightened scrape in boilers, where HVOF coatings are proper & employed.

Features of Plasma Spray Gun

- Extremely powerful (40 kW @ 100% duty cycle).

- Elevated warmth production (as far as 16000 degrees Celsius).

- Plasma gas speed can reach 3050 m/s.

- Particle accelerations of as far as 610 m/s.

- The Plasma HVOF spray gun system is easy & adaptable.

- The plasma spray gun size is small.

- Procedure, supervision, & installation are all simplified.

- A full spectrum of nozzle & powder port parts are available.

- Double Gas Capacity- uses argon or nitrogen as main plasma gas.

Plasma Spray Gun price

Ambica Enterprises is one of the best Plasma spray gun manufacturers and suppliers of Plasma Hvof spray guns in India. Plasma spray gun price depends on the type of Plasma spray gun. We provide all types of thermal spray guns, thermal spray powder, thermal spray wires, powder feeder, mineral powder, abrasive media, abrasive blasting machines, spare parts, etc.